Top entry agitator in suspension buffer tank, Kagayaki-project

On behalf of Worley The Netherlans, Veenstra has supplied Teijin Aramid in Delfzijl with an agitator for the Kagayaki project. The production location in Delfzijl handles the polymerization of raw materials for the production of Twaron. The mixture in the buffer tank, which must be kept homogeneous and in suspension, consists of the solvent NMP, CaCl2 and H2O containing, among other things, solids such as needle crystals.

Read more

Background

The Eemshaven has undergone considerable development in recent years. In 2019, Teijin, the producer of super fiber Twaron, announced that they were going to expand in Emmen and Delfzijl. Out of the golden-yellow Twaron fibres, various products for the international market are made. The Twaron fibers are applied to reinforce materials such as car tires, but they are also applied for manufacturing bulletproof vests. The Twaron fiber is currently made from fossil raw materials, but in the future it will be produced from biobased raw materials, reducing the negative environmental impact of the production process. For Twaron’s raw material, the two monomers PPD and TDC are combined in a closed process. All auxiliary materials are recovered via a factory specially developed for this purpose.

Scope of delivery

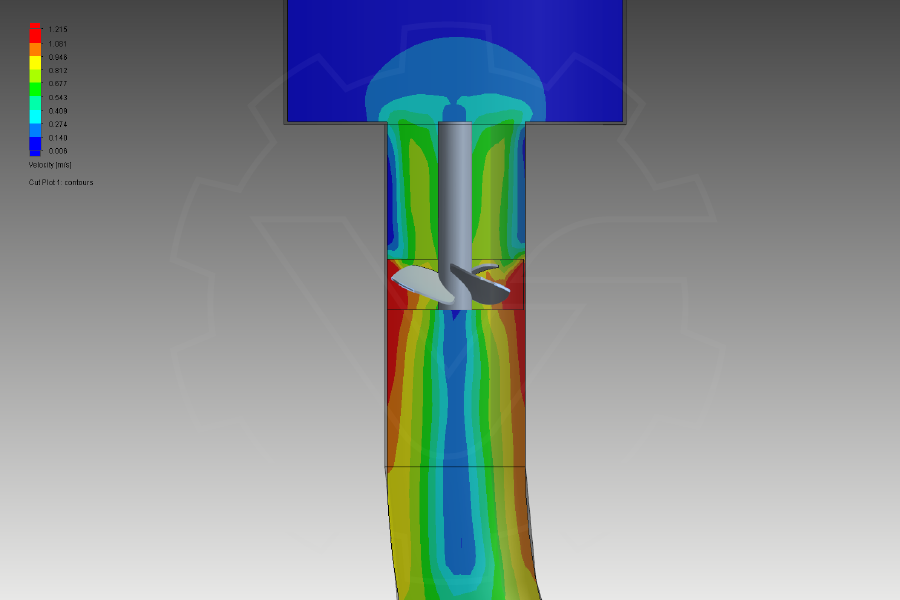

The delivery concerns an agitator with a cantilevered rudder shaft, equipped with one 4-blade marine propeller with a diameter of 840mm. The agitator drive consists of a 3kW flameproof motor in combination with a planetary gear fitted with an IEC-K2 adapter. The output speed of the gear unit is approximately 115rpm. In combination with the propeller, a pump capacity of approximately 40m3/min is achieved. The shaft seal of the agitator consists of a double-acting dry-running nitrogen mechanical seal, including N2 gas supply system.

Design requirements

The agitator is designed and built for continuous use at full load. The agitator is easy to maintain. The agitator consists of various components that can be replaced individually. Except from the drive motor and the mechanical seal, all components are manufactured by Veenstra. The 4-blade marine propeller is designed to easily be installed and removed through the manhole in the tank.