Fluidized sub-cone for optimal production flow

Veenstra has delivered a customized silo conversion for an existing production site in the plastics/polymer industry, replacing the old vibrating bottom with a fluidized undercone. This upgrade has significantly improved product flow and prevents blockages that regularly occurred in the old situation.

Read more

Project scope: fluidization and silo optimization

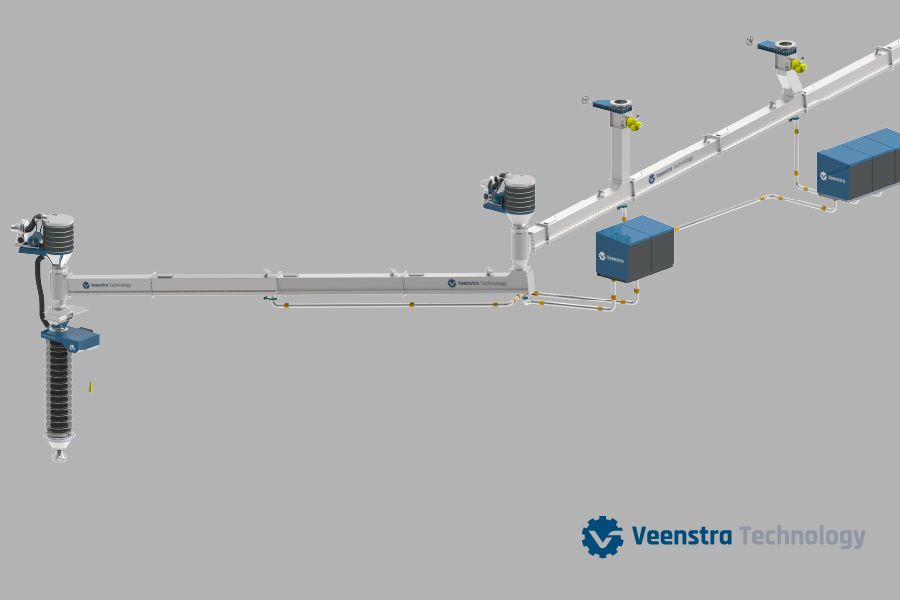

Veenstra carried out the entire process from design and production to delivery and commissioning of the new bottom cone. The customer modified the existing silo outlet in accordance with our technical specifications, after which our team tested the system and made it operational. The new system consists of the following main components:

- Fluidized sub-cone, Ø1200mm top connection – Ø300mm bottom connection, H=600mm*

- Outer cone with 3/4 internal sections fitted with air-permeable fabric

- Air distributor and pressure regulator

- Air hoses and all necessary connections

- Counterflange with rubber sleeve for coupling to the existing silo

- New manual valve for maintenance, installed between the lower cone and the screw conveyor

Challenge in the existing silo outflow

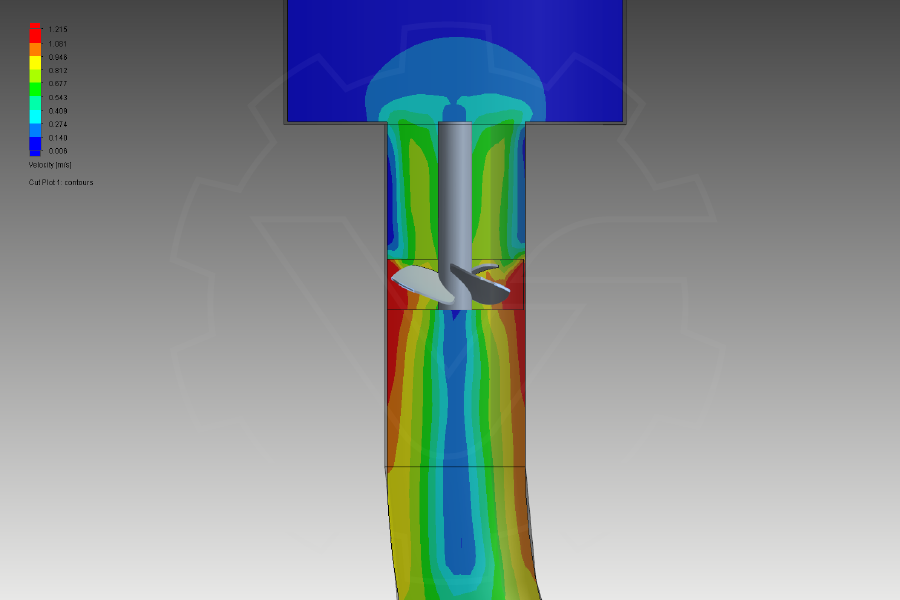

In the original situation, the vibrating base under the silo regularly caused blockages and downtime. The pads provided only limited support, as virtually no effective fluidization took place in the vibrating floor. Due to the relatively flat cone angle, materials easily became stuck, making the outflow unpredictable and requiring more frequent maintenance. This led to inefficient material throughput and ultimately low operational reliability.

Solution with fluidized subcone

Veenstra replaced the entire vibrating base with a fluidized lower cone with a steeper angle of repose, ensuring that the product is loosened evenly and flows continuously toward the screw conveyor. By also renewing the feed piece above the conveyor, extra height could be utilized for optimal product flow. This customized solution ensures stable, trouble-free outflow, less maintenance, lower downtime costs, and significantly higher operational reliability.